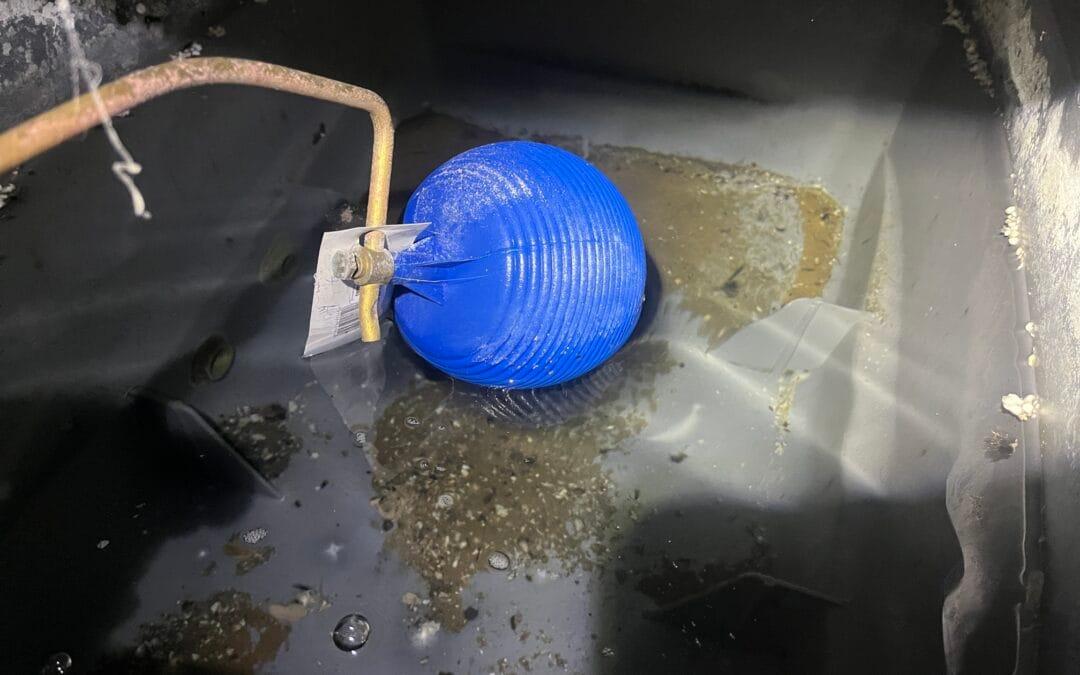

Tucked away in lofts, plant rooms, and rooftops, water tanks quietly shoulder a daily task: holding the clean water that homes, schools, hospitals, and businesses depend on. In the UK-where hard water, temperature swings, and a mix of historic and modern buildings all play their part-these silent reservoirs can accumulate sediment, limescale, and biofilm over time. Left unchecked, that build-up can affect water quality, system efficiency, and, in some cases, safety.

Water tank cleaning services exist to reset that balance. From inspection and risk assessment to mechanical cleaning and disinfection, professional teams help keep stored water systems hygienic and compliant. Many providers work to recognised UK guidance for water hygiene and legionella control, such as HSE’s ACoP L8 and HSG274 Part 2, and issue post-clean records for peace of mind and audit trails.

This article explores how water tank cleaning works in the UK context: what’s involved in a typical service, how often it’s needed, the signs your tank may require attention, and what to look for when choosing a provider-whether you manage a single domestic tank or a complex commercial estate.

Table of Contents

- What UK regulations require for water tank cleaning and Legionella control

- Cleaning and disinfection methods that work and when to choose chlorination, hydrogen peroxide or ultraviolet

- How to choose a qualified contractor with checks for industry memberships, risk assessments and method statements, insurance and UKAS accredited lab testing

- Recommended schedules, realistic costs and maintenance tips for homes and commercial sites

- The Way Forward

What UK regulations require for water tank cleaning and Legionella control

HSE guidance and UK law set clear expectations for employers, landlords, and facilities managers: carry out a competent Legionella risk assessment, maintain a written scheme of control, and prove that tanks and distribution systems are kept clean and safe. The legal backbone includes the Health and Safety at Work etc. Act, the Management of Health and Safety at Work Regulations, COSHH (for biological agents), and the HSE’s ACOP L8 with HSG274 Part 2 for hot and cold water systems. Design and hygiene standards also fall under the Water Supply (Water Fittings) Regulations 1999 (e.g., wholesome materials, sealed lids, screened vents/overflows, and protection against backflow). You must appoint a Responsible Person, ensure training/competence, verify temperature control (hot ≥60°C at source and ≥50°C at outlets; cold ≤20°C), and keep auditable records.

- Appoint and train a competent dutyholder/Responsible Person and keep role clarity in writing.

- Complete and regularly review a Legionella risk assessment (BS 8580-1) with a written scheme for tanks and outlets.

- Maintain temperature control, flow/turnover, and eliminate stagnation (flush little‑used outlets).

- Inspect tanks for integrity, cleanliness, and screening; clean/disinfect when inspection or results dictate.

- Use WRAS‑approved materials and follow BS 8558/EN 806 for potable water hygiene; sample to BS 7592 when indicated by risk.

- Record everything (monitoring, remedials, certificates) and retain evidence for at least five years.

| Control task | Typical minimum frequency |

|---|---|

| Flush little‑used outlets | Weekly |

| Sentinel temperature checks | Monthly |

| Cold water tank temperature | Monthly |

| Tank condition/lid/screens inspection | 6‑monthly |

| Clean and disinfect tank | As required by inspection/risk |

| Risk assessment review | Annually or on change |

| Microbiological sampling | When indicated by risk |

For cleaning and disinfection, regulators expect a method statement and RAMS, isolation/permits, controlled dosing, validation (e.g., neutralisation, flushing, and certificate of disinfection), plus reinstatement checks so occupants are protected. Systems should avoid dead legs, ensure adequate turnover, and restore compliant temperatures quickly after works. Where results fall outside control limits, escalate via your escalation protocol (e.g., resampling, shock disinfection, remedial plumbing). Consistent, evidence‑based routines aligned to ACOP L8/HSG274-and documented with clear signage, logs, and contractor competence-demonstrate due diligence and reduce enforcement risk.

Cleaning and disinfection methods that work and when to choose chlorination, hydrogen peroxide or ultraviolet

In the UK, effective tank hygiene pairs a thorough physical clean with a targeted kill step that suits your water chemistry, materials and risk profile. After isolating and draining, remove sediment and biofilm (scrub, wet‑vac, low‑pressure rinse) so the biocide can contact every surface. Then apply a controlled dose with the right dwell time, neutralise where needed, refill, flush and verify with microbiological sampling for TVC and Legionella in line with ACOP L8, HSG274 Part 2 and BS 8558. Think of it as: clean → dose → dwell → prove.

- Mechanical prep amplifies biocide performance by disrupting biofilm.

- Coverage + contact are critical; stagnant pockets undermine results.

- Residual management protects fixtures and ensures safe return to service.

- Records and certificates close the loop for compliance and audits.

| Method | Typical Action | Advantages | Best Use |

|---|---|---|---|

| Chlorination | ~20-50 mg/L free Cl for 1-2 h | Broad spectrum; measurable residual; familiar | Post‑repair, first cleans, extensive networks |

| Hydrogen peroxide | ~50-100 mg/L (stabilised) for 1-4 h | Low odour; biofilm penetration; oxygen/water by‑products | Odour‑sensitive sites; mixed materials; remedial cleans |

| Ultraviolet (UV) | ~254 nm, ≥40 mJ/cm² at point of use | Instant; chemical‑free barrier | Point‑of‑entry polish; pair with filtration and periodic chemical clean |

Choose chlorination when you need fast, system‑wide control, a verifiable residual, or when tackling visible fouling and complex pipework. Opt for stabilised hydrogen peroxide where taste/odour neutrality matters (healthcare, food and drink), where materials benefit from a gentler profile, or where biofilm resilience is suspected. Deploy UV as a non‑chemical safeguard at inlets or critical outlets-especially where storage and handling of chemicals are constrained-while remembering it provides no residual; combine it with pre‑filtration and scheduled chemical disinfection to manage downstream regrowth. Balance pH, temperature, hardness, and material compatibility (elastomers, stainless, galvanised) with site operations to select the safest, compliant route that keeps tanks clean and evidence ready for audit.

How to choose a qualified contractor with checks for industry memberships, risk assessments and method statements, insurance and UKAS accredited lab testing

Choosing a partner for water hygiene is about proof, not promises. Look for visible, current credentials and documentation that map to UK guidance and standards. Prioritise contractors with verifiable industry memberships, tailored Risk Assessments and Method Statements (RAMS), adequate insurance lines, and UKAS-accredited water testing routes. Ask for evidence that their team is trained, their methods are safe and repeatable, and their results are independently validated.

- Industry memberships: Prefer providers registered with the Legionella Control Association (LCA), supported by training via WMSoc or equivalent, and H&S schemes like CHAS or SafeContractor. Request current certificates and service scopes.

- Risk assessments & method statements (RAMS): Ensure RAMS reference HSE ACoP L8 and HSG274 Part 2, include COSHH for disinfectants, access controls, by-product management (e.g., neutralisation), confined-space protocols, and calibration logs for testing equipment.

- Insurance: Confirm active Public Liability, Employers’ Liability and, for consultancy/reporting, Professional Indemnity. Ask for limits, expiry dates and a statement covering water treatment activities.

- UKAS lab testing: Legionella and TVC sampling should go to a UKAS (ISO/IEC 17025) accredited laboratory using recognised methods (e.g., ISO 11731). Request chain-of-custody, method detection limits and turnaround times.

| What to check | Why it matters | Ask for |

|---|---|---|

| LCA membership | Assures audited service delivery | Current certificate + service categories |

| RAMS (job-specific) | Safety, compliance and traceability | HSE L8/HSG274 references + COSHH sheets |

| Insurance cover | Risk transfer if something goes wrong | PL/EL/PI schedules with limits & expiry |

| UKAS lab tests | Independent verification of water quality | UKAS number, ISO method, CoC, sample plan |

Before you sign, request sample deliverables: a templated RAMS for your site, a scope of works detailing cleaning/disinfection chemistry and contact times, and a report pack example showing pre- and post-clean photographs, flushing logs, residual biocide readings, and UKAS-backed microbiological results. A credible contractor will also offer a sampling plan aligned to system risk, provide close-out actions when results exceed limits, and update your asset register and written scheme so compliance remains intact long after the clean.

Recommended schedules, realistic costs and maintenance tips for homes and commercial sites

Homes in the UK generally benefit from visual checks quarterly and a full internal clean and disinfection every 6-12 months; bring this forward to 3-6 months for holiday lets, older loft tanks, or properties in hard‑water areas where scale and sediment accumulate faster. Commercial sites should set frequencies by a Legionella risk assessment (HSE L8/ACOP compliant): weekly flushing of little‑used outlets, monthly temperature checks and inspection, 6-12‑monthly cleans, and 3-6‑monthly cycles for higher‑risk settings such as healthcare, gyms, and care homes. Trigger a clean immediately after plumbing works, contamination events (e.g., pests, debris, discoloured water), or if odour, staining, or slime appears-regardless of the calendar.

Expect realistic costs to vary by tank size, access, and compliance requirements. Typical domestic cleans for a single tank up to 1,000 L fall around £120-£280 (disinfection included), with optional microbiological sampling at £40-£90 per test. Small communal or larger domestic systems (1-5 m³) generally range £300-£650. Commercial tanks of 5-20 m³ usually sit between £450-£1,200, while multi‑tank plants, restricted access, or out‑of‑hours work can elevate pricing; service plans and grouped visits often reduce spend by 10-20%. To stretch budgets, align cleaning with scheduled shutdowns, combine with TMV servicing, and maintain clear access so technicians spend time on the tank-not on obstacles.

| Item | Homes | Commercial |

|---|---|---|

| Visual checks & flushing | Weekly flush little‑used taps; quarterly lid/overflow check | Weekly flushing; monthly inspection per risk assessment |

| Temperature checks | Annually (DIY or contractor) | Monthly (sentinel outlets), recorded in logbook |

| Deep clean & disinfection | Every 6-12 months; sooner if debris/odour | 6-12 months; 3-6 months in high‑risk sites |

| Microbiological sampling | Optional or after issues | Every 3-6 months if medium/high risk |

| Typical cost (per visit) | £120-£280 (≤1,000 L); sampling £40-£90/test | £450-£1,200 (5-20 m³); sampling £40-£90/test |

| Best time to book | Spring or autumn; before peak holiday use | Planned shutdowns; off‑peak trading hours |

- Seal and screen lids, overflows and vents to keep out insects and debris.

- Flush rarely used outlets weekly to prevent stagnation and odours.

- Target temperatures: cold below 20°C, hot stored at 60°C+ to curb bacterial growth.

- Fit a sediment pre‑filter and consider a tank jacket in lofts to reduce thermal swings.

- Keep a simple logbook with dates, observations and photos to spot trends early.

- Appoint a Responsible Person and maintain an L8‑aligned scheme of control with records.

- Label assets and valves for faster isolations and safer interventions.

- Bundle tasks: combine tank cleans with TMV servicing and calorifier checks to save call‑outs.

- Verify competence: confined‑space trained operatives, disinfection certification, and safe waste disposal.

- Schedule sampling smartly (e.g., routine 3-6 months or after changes in use) for actionable trend data.

The Way Forward

In the end, clean water storage is less about what you see and more about what you never have to think about. Behind every clear glass and steady tap sits a quiet system that depends on routine attention, documented checks, and competent hands. In the UK’s framework of guidance and regulation, effective tank cleaning isn’t a one-off chore but part of a living maintenance plan that protects health, preserves assets, and keeps operations compliant.

If this article has a single takeaway, it’s to make invisibility your goal: risks managed before they surface, schedules set before issues arise, and records ready before anyone asks. Review your logbook, confirm your risk assessment is current, and align cleaning and disinfection with actual usage and system design. When you do engage a provider, look for clear method statements, evidence of training and insurance, safe entry procedures, and post-clean testing with transparent reporting.

Water moves on; responsibility stays. A measured approach today-grounded in HSE guidance, good practice, and tidy documentation-keeps your system quietly reliable tomorrow.