From terraced houses lashed by coastal rain to glass-and-steel towers rising over the Thames, “clean” in the UK spans a mosaic of places, people, and expectations. It is a practical ritual shaped by climate and culture-muddy winters and hard water, cramped Victorian stairwells and open-plan offices-and a professional industry governed by standards, safety rules, and tight margins. Cleaning here is as much about compliance and confidence as it is about sparkle: COSHH labels on bottles, method statements on clipboards, and a quiet choreography that keeps hospitals sterile, trains on time, hotels review-ready, and rental deposits intact.

This article explores the landscape of UK cleaning in full: the domestic routines and end-of-tenancy deep cleans that define the private sphere; the commercial contracts that run on schedules, SLAs, and audit trails; and the specialist work of healthcare, hospitality, education, and transport. We’ll examine how technology-from microfiber to robotics-sits alongside elbow grease, why sustainability now shapes purchasing and processes, and how regulation, accreditation, and insurance set the baseline for trust. We’ll look at the workforce that powers it all, from sole traders to nationwide providers, and at regional differences that influence both demand and delivery.

Whether you’re hiring a service, managing a facilities budget, or simply trying to keep limescale at bay, understanding how UK cleaning really works can save time, money, and friction. What follows is a practical guide to the systems behind the shine-and to the everyday decisions that keep homes habitable, workplaces safe, and public spaces welcoming across the country.

Table of Contents

- Navigating UK Cleaning Compliance from COSHH Risk Assessments to REACH Safety Data

- Choosing Eco Friendly Products That Tackle Hard Water Limescale and Carry Trusted Ecolabels

- Designing Site Specific Schedules with Room by Room Checklists and Seasonal Task Rotations

- Proving Results Through Swab Testing Audit Trails and Service Level KPIs

- Insights and Conclusions

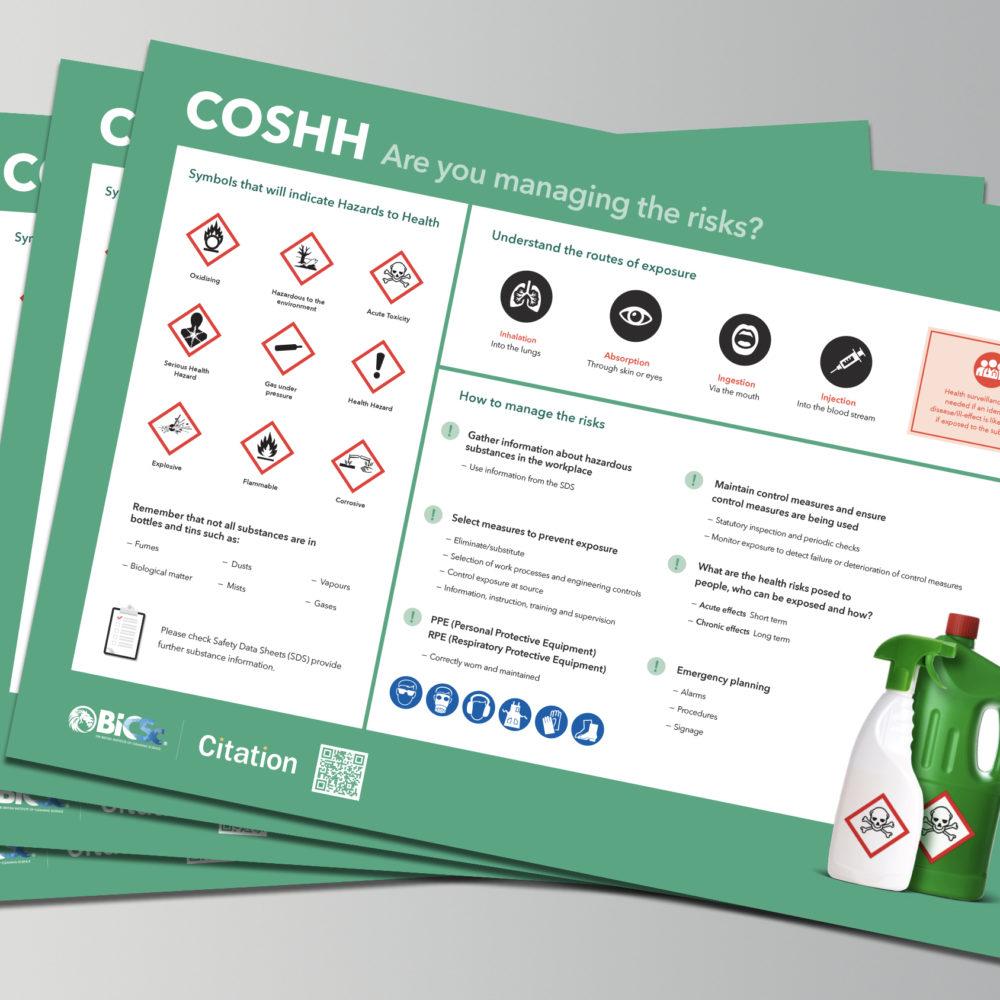

Navigating UK Cleaning Compliance from COSHH Risk Assessments to REACH Safety Data

Compliance in cleaning hinges on connecting the dots between COSHH risk assessments, CLP labels, and UK REACH Safety Data Sheets (SDS) so that products, tasks, and people are managed as one system. Build assessments around the way work actually happens-dilution, decanting, contact time, ventilation, and waste-then translate the findings into clear controls on the floor.

- Inventory every substance: trade/technical name, use, and location.

- Retrieve current SDS (UK REACH-aligned) and verify Sections 2, 8, and 13 match site practice.

- Task-based COSHH: exposure routes, frequency, by‑products (e.g., aerosols, vapours).

- Controls: engineering (ventilation), admin (rota, restricted access), PPE, emergency response.

- CLP labelling for decanted containers; no orphan bottles, no faded pictograms.

- Substitution where feasible (lower hazard, closed systems, pre‑dosed formats).

- Training and records that mirror reality: method statements, signage, spill drills.

| Document/Rule | Focus | Practical checkpoint |

|---|---|---|

| COSHH Assessment | Task risk + controls | Is dilution/contact time stated? |

| UK REACH SDS | Hazards + safe use | Section 8 matches issued PPE? |

| CLP Label | Pictograms/H-phrases | Decanted bottles correctly marked? |

| DSEAR | Flammables/ignition | Aerosols stored away from heat? |

| Waste Notes | Disposal traceability | Segregation and contractor details? |

Evidence closes the loop: keep review dates, versioned methods, and calibration logs for dosing systems; track near misses, dermatitis reports, and exposure monitoring where sensitisers are used. Any change-new fragrance, altered viscosity, different supplier-triggers a reassessment and an SDS check for updated limits or incompatible reactions. Align GB‑only supply chains with UK REACH (not just EU REACH), verify supplier details on SDS, and maintain simple visual standards in stores: segregate acids/alkalis, lock hazardous products, and keep spill kits serviceable. The goal is seamless translation from paperwork to practice-clean, safe, and demonstrably compliant.

Choosing Eco Friendly Products That Tackle Hard Water Limescale and Carry Trusted Ecolabels

In hard-water postcodes, scale builds up fast-on taps, tiles, and inside kettles-so choose formulas that cut mineral deposits without harsh residues. Look for plant-derived acids like citric or lactic acid and modern biodegradable chelators such as GLDA/MGDA; they dissolve limescale while staying kind to waterways. Skip dyes-heavy or high-VOC blends and prioritise fragrance-free or allergen-screened options for small bathrooms. Trust marks matter: third‑party schemes verify biodegradability, aquatic safety, and proven cleaning performance, not just green wording on the bottle.

- Read the INCI: Short lists with citric/lactic acid and plant-based surfactants signal cleaner chemistry.

- Pick formats wisely: Gels cling to vertical limescale; foams spread evenly; concentrated refills cut plastic.

- Check water-compatibility: Claims like “hard water tested” or “fitness-for-use” indicate real-world performance.

- Mind surfaces: For natural stone, choose pH-balanced formulas and spot-test, as acids can etch.

- Packaging counts: Prefer PCR plastic, aluminium, or closed-loop refill systems.

For everyday maintenance, pair an eco descaler with a microfibre cloth, wipe after steamy showers, and descale fixtures weekly to prevent crusting. When comparing products in UK shops or refill stores, lean on independent ecolabels that set limits on hazardous substances, require performance testing, and reward circular packaging-so your limescale remover works hard without compromising waterways or indoor air.

| Ecolabel | What it assures | Where you’ll see it |

|---|---|---|

| EU Ecolabel | Biodegradability, low aquatic toxicity, performance tests | UK supermarkets; mainstream bathroom descalers |

| Nordic Swan | Strict chemical limits, effective in hard water | Scandi imports; select UK eco ranges |

| ECOCERT Detergents | Natural-origin content and cleaner chemistry | Refill stations; specialist eco brands |

| Cradle to Cradle Certified | Material health and circular packaging | Concentrates; reusable bottles |

| Blue Angel | Low emissions and reduced pollutants | EU imports; online eco retailers |

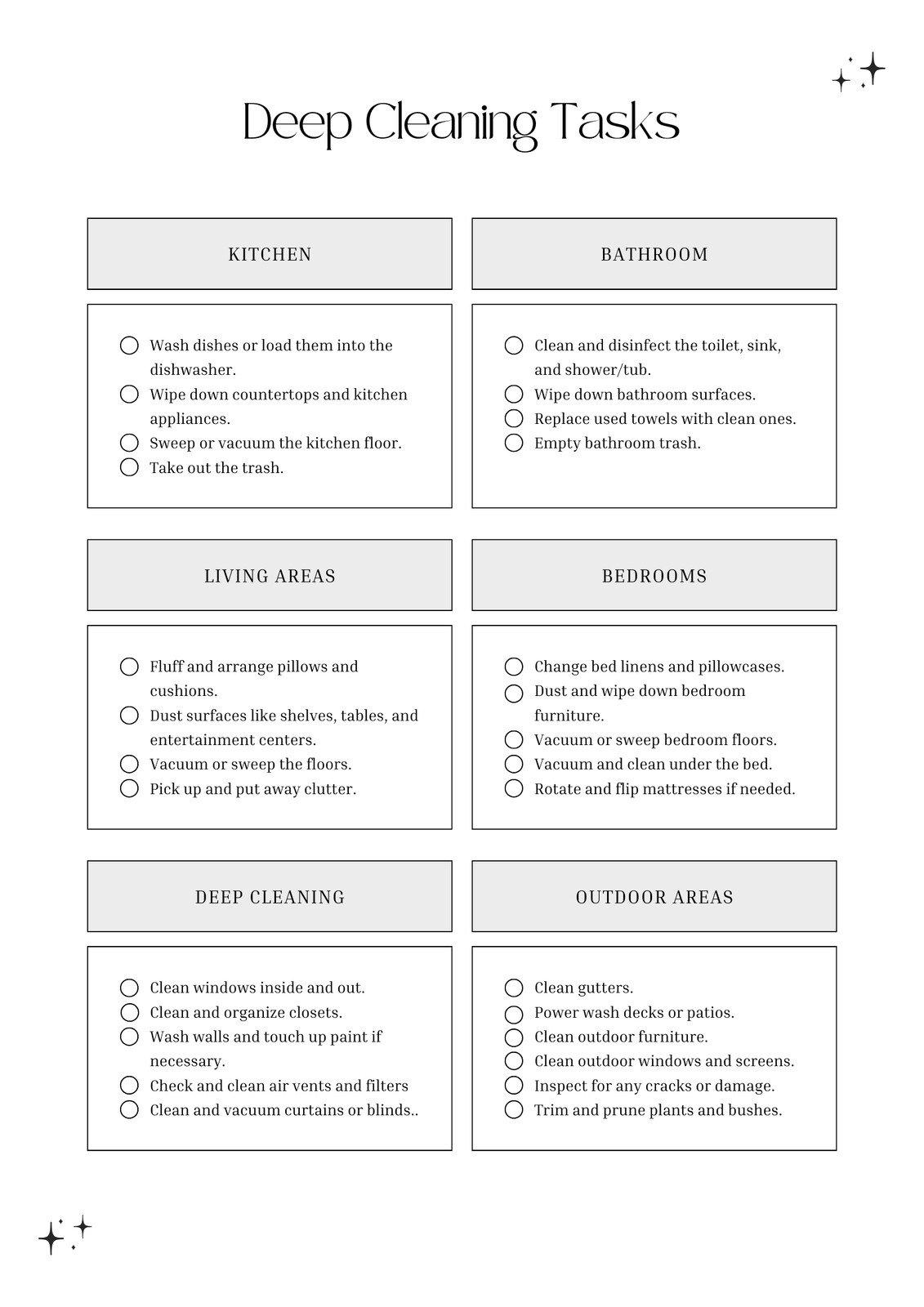

Designing Site Specific Schedules with Room by Room Checklists and Seasonal Task Rotations

Start with a site walk-through and convert what you see into a living plan: map zones, note surface types, traffic patterns, and regulatory pinch points. Translate each space into a concise checklist with clear scope, frequency, method, materials, and quality checks. Anchor timings to footfall and risk, not guesswork, and keep everything visible-laminated cards on trolleys, QR-coded checklists on doors, and a weekly dashboard for managers. Build in variance for special spaces common across UK sites (heritage finishes, healthcare rooms, server racks) and define fail-safes for absences so standards hold even on lean staffing days.

- Reception/Entrance: Edge-to-centre floor care, finger-mark removal on glass, matting shake-out, fragrance-neutral air refresh.

- Washrooms: Touchpoint disinfection, descaling schedule by water hardness, stock counts (paper/soap), odour control vents.

- Kitchen/Tea Points: Crumb traps, kettle bases, fridge seals, spill logs, food-safe sanitiser rotation.

- Desks/Offices: Monitor edges, cable nests, chair bases, bin and recycling split, low-noise vac windows.

- Meeting Rooms: Table undersides, chair backs, AV remotes, glass boards, air vents.

- Stairs/Lifts: Nosing and riser dust, handrail wipe-downs, lift button panels, track debris.

| Season | Rotation Focus | Quick Add‑ons |

|---|---|---|

| Spring | High dusting, vents, blinds | Allergy-friendly vac bags; window tracks |

| Summer | Pollen control, fans, screens | Door glass polish; bin odour tabs |

| Autumn | Entrance mats, leaf ingress | Hinge wipes; carpet spot map |

| Winter | Grit/salt residue, moisture | Wet-floor checks; radiator dust |

Rotate tasks by British weather patterns and local realities: more mat maintenance and mopping passes after wet commutes, extra glass care on bright days, and stepped-up touchpoint hygiene during peak illness waves. Use mini-swaps to keep hours steady (e.g., trade a daily glass polish for an extra mop cycle when grit is down), and log exceptions from audits and callouts to refine next week’s plan. Keep consumables consistent with site policy-COSHH-compliant products, microfibre colour-coding, and low-VOC choices-so your schedule scales across multi-site portfolios without losing the exacting detail of a room-by-room checklist.

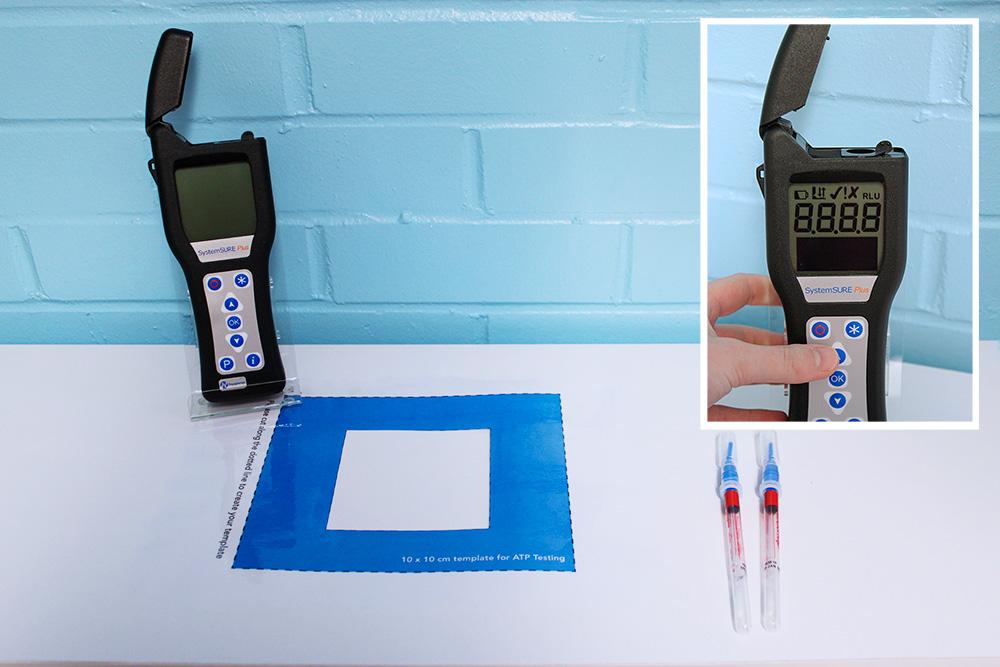

Proving Results Through Swab Testing Audit Trails and Service Level KPIs

In the UK cleaning landscape, the most credible way to show hygiene performance is to pair science-led swab sampling with a verifiable digital record. Each sample is time-stamped, site-zoned, and linked to the exact surface via QR/RFID, with ATP/CFU readings matched to risk-tier tolerances. Photo evidence, operative ID, and supervisor sign-off complete a defensible trail that stands up to CQC, BRCGS, and UKHSA-aligned audits while staying GDPR-safe. Trend analysis across shifts, zones, and seasons reveals hotspots, informing targeted retraining and product tweaks for measurable, sustained uplift.

- Surface ID & zone: QR/RFID coded for traceability

- Pre/post readings: RLU/CFU against baseline tolerances

- Method & chemistry: process, dwell time, batch/lot

- People: operative ID, supervisor e-sign, competency

- Evidence: photos, anomalies, re-clean notes

- Standards map: NHS, BRCGS, ISO references

Service delivery then turns into clear scorecards, where schedule adherence, hygiene pass rates, first‑time pass outcomes, and response times are tracked against site-specific KPIs. Targets flex by risk-tier (clinical, food prep, public areas), with threshold breaches triggering escalation, root-cause analysis, and client-facing updates. Live dashboards connect proof-of-clean to cost per m² and sustainability metrics, making contract reviews evidence-led rather than anecdotal, and ensuring consistent, transparent performance across portfolios.

| KPI | Target | Evidence | Action Trigger |

|---|---|---|---|

| Touchpoint ATP | ≤ 50 RLU | Swab log + photo | > 50 RLU → re-clean + supervisor check |

| Schedule adherence | ≥ 98% | CAFM & clock‑ins | < 98% → roster re-balance |

| Critical response | < 60 min | Incident ticket | Missed SLA → on-call escalation |

| First-time pass | ≥ 95% | QA audits | < 93% weekly → micro‑training |

| Re-clean rate | ≤ 3% | Audit outcomes | > 3% (3 days) → method review |

Insights and Conclusions

In the end, UK cleaning is less a single service than a quiet choreography-moving from first light to last lock-up, from rain-polished pavements to offices that reset while the city sleeps. It spans centuries-old stone and new-build glass, public spaces and private rooms, regulated standards and the everyday judgment of what “good” looks like. Behind the scenes, it supports health, reputation, and routine, often noticed only when it stops.

As the sector adapts-leaning into low-impact chemicals, smarter scheduling, data-led audits, and better training-the essentials remain clear: clear expectations, fair work, measurable outcomes, and methods that fit the place as well as the budget. The tools will change; the reasons won’t.

Whether you manage a high street shop, a school corridor, or a distribution hub on the edge of town, the next step is practical: define what matters, choose partners who can evidence it, and keep the conversation going. Cleaning is not the main event of British life, but it is the stagehand that makes the show possible-steady, precise, and ready again tomorrow.