From the outside, a construction project can look like a simple sequence of steps: design, build, deliver. Up close, it behaves more like a living system-permits and plans intersecting with budgets, schedules, weather, materials, and dozens of specialised teams. For many owners, the hardest part isn’t laying the foundation; it’s orchestrating all the moving parts without losing sight of the original vision.

Enter the full-service construction company. Rather than dividing responsibility among separate designers, engineers, subcontractors, and project managers, a full-service firm brings these functions under one roof. The result isn’t just convenience. It can mean clearer accountability, fewer handoffs, and a project narrative that stays coherent from the first site walk to the final punch list. Whether you’re renovating a retail space or breaking ground on a multi-phase development, this integrated construction service approach can help tame complexity-streamlining communication, aligning decisions with constraints, and reducing the friction that often leads to delays and rework.

This article explores the practical benefits of hiring a full-service construction company, where those advantages are most pronounced, and the trade-offs to consider. You’ll find guidance on cost visibility, risk management, schedule control, quality assurance, safety, and sustainability-plus key questions to ask prospective partners so you can choose the delivery model that best fits your goals.

Table of Contents

- Integrated design to occupancy delivery that reduces rework and complexity: ask for early contractor involvement and a single source of truth

- Predictable costs and schedules through open book estimating and realistic contingencies: request weekly look ahead schedules and transparent change logs

- Centralized risk, permits, and compliance oversight that protects budget and timeline: define escalation paths and safety KPIs upfront

- Performance gains from BIM, prefabrication, and sustainable procurement: insist on clash detection before procurement and product EPDs for key materials

- Final Thoughts

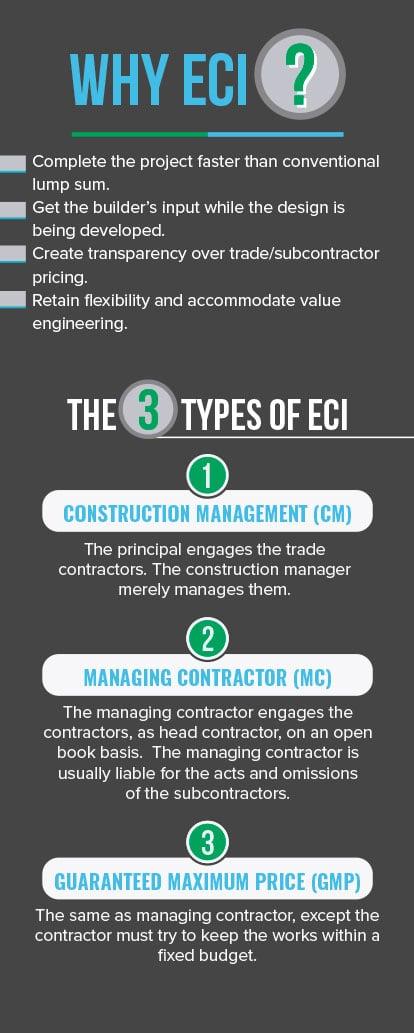

Integrated design to occupancy delivery that reduces rework and complexity: ask for early contractor involvement and a single source of truth

Bring the builder to the table on day one and keep every decision, drawing, and cost in a single, living platform. With early contractor involvement, constructability, logistics, and budget intelligence inform design in real time, turning guesswork into grounded choices. A single source of truth-from models and specs to RFIs and submittals-keeps architects, engineers, trades, and owners aligned, so details don’t get reinvented downstream. The result is a seamless handoff from concept through commissioning, where information flows forward, not sideways, and rework gives way to reliable progress.

- Fewer surprises: clashes resolved in design, not in the field

- Cleaner documentation: standardized submittals and updated drawings in one place

- Faster decisions: real-time cost/schedule impacts visible to all

- Procurement clarity: long-lead items prioritized early

- Commissioning-ready: testing, training, and O&M data captured as you build

| Phase | Lead | Key Output |

|---|---|---|

| Concept | Owner + GC | Targets & Budget Guardrails |

| Design | AE + GC | Clash-Free Model & Plan |

| Procure | GC | Locked Long-Lead Strategy |

| Build | GC + Trades | Field-Ready Details |

| Commission | GC + Owner | Verified Systems & O&M |

| Occupy | Owner | Digital Handover & Training |

Full-service delivery tightens the feedback loop from precon to punchlist. By anchoring the team to one platform and one accountable partner, you compress timelines, reduce change orders, and simplify closeout. Owners gain traceable decisions, trades build from current information, and facility teams inherit a clean digital record-so the building works as designed on day one, and keeps working effortlessly on day 1,000.

Predictable costs and schedules through open book estimating and realistic contingencies: request weekly look ahead schedules and transparent change logs

Open-book estimating turns preconstruction into a transparent workshop, where every labor hour, material unit, and subcontractor quote is visible and traceable. By pairing this clarity with realistic contingencies-calibrated to market volatility, lead times, and site complexities-you get an honest picture of cost exposure from day one. Ask for a living estimate that evolves with design milestones, plus a contingency plan with clear release rules, so budget adjustments are predictable rather than surprising.

Schedule predictability thrives on rhythm. Weekly look-ahead schedules give you a rolling, task-level view tied to the critical path, while transparent change logs show scope decisions, cost impacts, and date shifts in real time. This cadence ensures faster approvals, fewer bottlenecks, and a shared understanding of what’s next-so you can steer proactively instead of reacting late.

- Budget clarity: Line-item visibility and variance tracking minimize guesswork.

- Schedule confidence: Short-interval planning exposes roadblocks early.

- Risk control: Contingency usage is documented, justified, and time-stamped.

- Decision speed: Clear change narratives shorten review cycles.

- Accountability: Audit-ready records align owners, designers, and builders.

| Document | What You See | Frequency | Owner |

|---|---|---|---|

| Open-Book Estimate | Line items + quotes | At milestones | Estimator |

| Look-Ahead Schedule | 2-week tasks | Weekly | Superintendent |

| Change Log | Scope + cost/date impact | Real-time | Project Manager |

| Contingency Tracker | Balance, usage, reason | Weekly | Project Controls |

Centralized risk, permits, and compliance oversight that protects budget and timeline: define escalation paths and safety KPIs upfront

With one accountable team stewarding approvals, inspections, and regulatory obligations, your project benefits from a single source of truth that links risk registers directly to the schedule and cost plan. This reduces handoff friction, accelerates agency coordination, and turns potential delays into actionable tasks with clear owners. Permitting roadmaps, environmental reviews, and insurance requirements are sequenced against milestones, backed by digital documentation and audit-ready trails-so you avoid rework, fines, and last‑minute fee surprises.

- Permit matrix aligned to jurisdictions and lead times

- Compliance calendar tied to inspections and deliverables

- Risk register with probability, impact, and mitigations

- Authority liaison to fast‑track clarifications

- Documentation vault for submittals, certificates, and closeout

Clear escalation architecture and measurable safety expectations are set on day one, so issues never drift. Response SLAs, stop‑work authority, and a defined RACI prevent small deviations from snowballing into budget busters, while leading and lagging indicators keep crews accountable. Near‑miss reporting, PPE adherence, and toolbox talk cadence are monitored alongside recordable incident rate to create a feedback loop that protects people and the timeline.

| Level | Trigger | Owner | Response SLA | Fail‑Safe |

|---|---|---|---|---|

| Field | Near‑miss, minor variance | Foreman | 2 hours | Pause task |

| Site | Permit risk, safety threshold | Superintendent | 8 hours | Stop‑work area |

| Executive | Critical path impact | Project Exec | 24 hours | Re‑sequence plan |

- TRIR target: ≤ 1.0

- Near‑miss ratio: 1 per 200 hours

- PPE compliance: 100% spot‑check

- Toolbox talks: 1 per crew/week

- Corrective action closeout: 48 hours

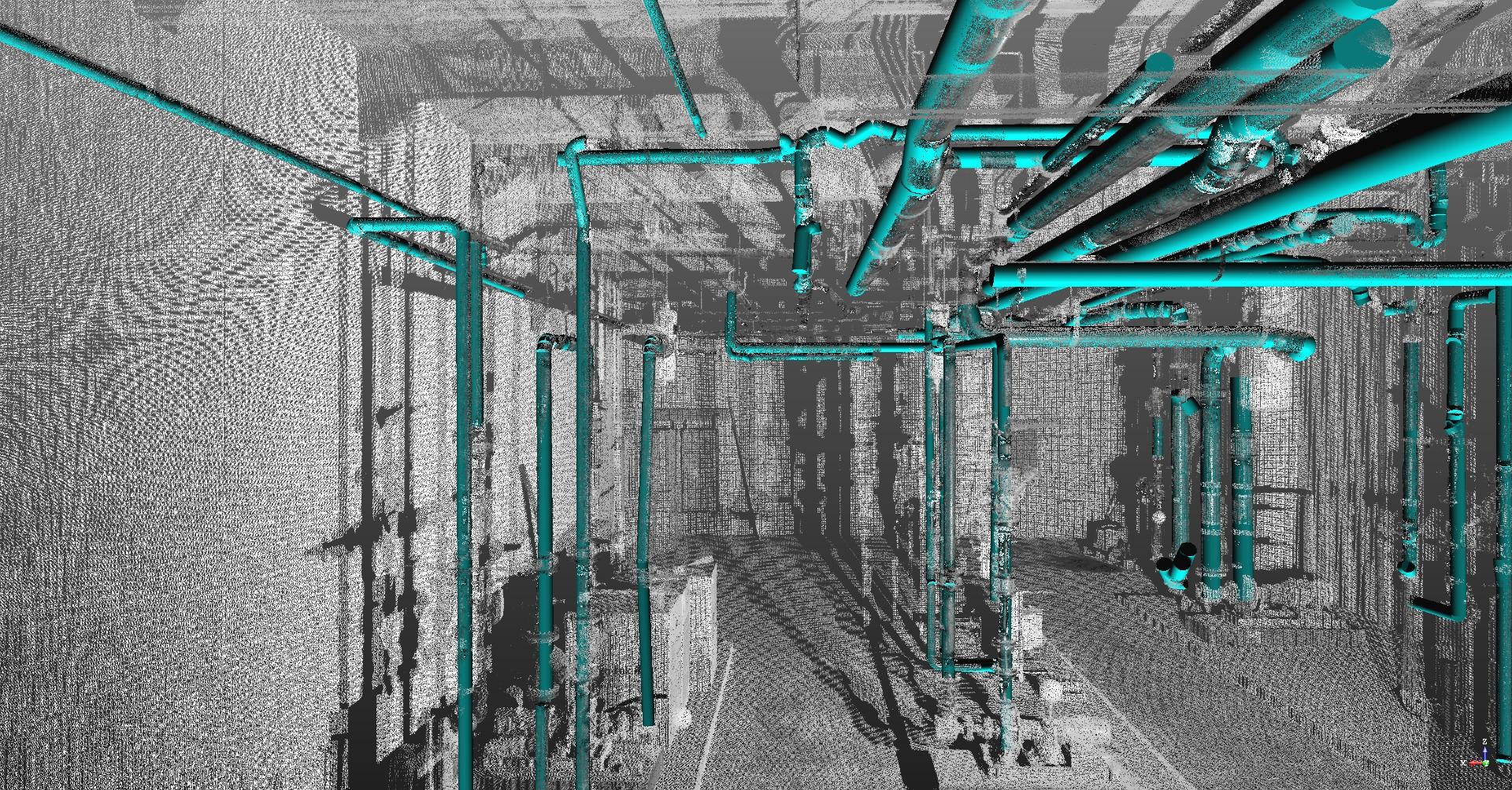

Performance gains from BIM, prefabrication, and sustainable procurement: insist on clash detection before procurement and product EPDs for key materials

BIM-led coordination turns a full-service team into a single, accountable source of truth: trades model their scopes, conflicts are surfaced early, and clash detection becomes a gate before any buyout. With procurement driven by a clash-free model, prefabrication can proceed with confidence-modules, MEP racks, and facade panels are fabricated off-site to exact tolerances, then installed rapidly with minimal disruption. The result is tighter cost control, cleaner schedules, and fewer surprises on site.

- Fewer RFIs and change orders thanks to model-first decisions

- Faster installation via repeatable, off-site assemblies

- Improved safety and reduced waste from controlled fabrication environments

- Cost certainty through quantity-driven procurement tied to the model

| Key Material | EPD | Unit CO2e | Lower-Carbon Option | Lead Time |

|---|---|---|---|---|

| Concrete C30/37 | Yes | ~280 kgCO2e/m³ | 40% SCM blend | +7 days cure |

| Structural steel | Yes | ~1.6 kgCO2e/kg | EAF mill supply | Standard |

| CLT panels | Yes | ~−0.7 kgCO2e/kg | FSC-certified | 8-10 weeks |

| Mineral wool | Yes | ~1.2 kgCO2e/m² | 75% recycled | Normal |

A full-service contractor aligns sustainable procurement with digital coordination, requiring EPDs for high-impact packages and tying embodied carbon targets to model quantities. This approach streamlines submittals, makes trade buyouts contingent on coordination sign-offs, and keeps carbon, cost, and schedule moving in lockstep-so owners gain compliance-ready documentation and measurable performance without slowing the build.

- EPD-backed submittals for concrete, steel, timber, insulation, and glazing

- Buyout gates linked to clash-free coordination reports

- Live carbon dashboards tied to quantity takeoffs

- Prefab mock-ups approved before full production

Final Thoughts

From first sketch to final punch list, a full-service construction company can be the single thread that keeps a project from unraveling-aligning design, permitting, trades, schedules, budgets, and closeout under one roof. The advantages are pragmatic: tighter coordination, clearer accountability, fewer handoffs, more predictable costs and timelines, and support that extends beyond the ribbon cutting.

It isn’t a universal solution. Owners with highly specialized designs or robust in-house oversight may prefer a different delivery model. But if your priorities lean toward cohesion and reduced friction, full-service is worth a hard look. Take the time to define your scope and success criteria, vet teams carefully, and choose the partner and process that fit your vision. The right build starts with the right way to build.